December 8, 2017 Firmware 1.02 for J1708 Engine Gateway

This update is designed for Volvo Penta KAD owners who have different readings on analog gauges and NMEA 2000 instruments. Read more to learn why many customers love our products, why our products are the best, and why we can't create barometer from your engine.

The J1708 Engine Gateway operates on digital data received from EDC unit. This means that it receives a number which must be converted and sent to NMEA 2000. For example, it receives 1080 as the Voltage from Volvo Penta KAD engine. 1 bit in KAD protocol is 0.0125V and the gateway must multiply 1080 by 0.0125 to get the actual voltage value (13.5V).

We have received reports from Volvo Penta KAD owners that voltage, coolant temperature and boost pressure readings on old analog gauges differ from the values on NMEA 2000 instrument fed by our gateway. But most questions are about boost pressure only.

Boost pressure in NMEA 2000 is absolute value (0..6553.2 kPa), and the analog gauge of KAD shows boost relative to atmospheric pressure (so the value can even be a bit less than zero). It is not correct to pass relative value to NMEA 2000, but it is also distracting to see different numbers. Moreover, KAD reports absolute and relative pressure both. Unfortunately, it is impossible to create a barometer from your engine, because the readings come with a delay and boost pressure readings are usually not stable enough to calculate atmospheric pressure with good quality (but we tried).

We have added the setting to the configuration file, and if you wish to see the same readings of boost pressure just set the following parameter to ON:

KAD_RELATIVE_BOOST=ON

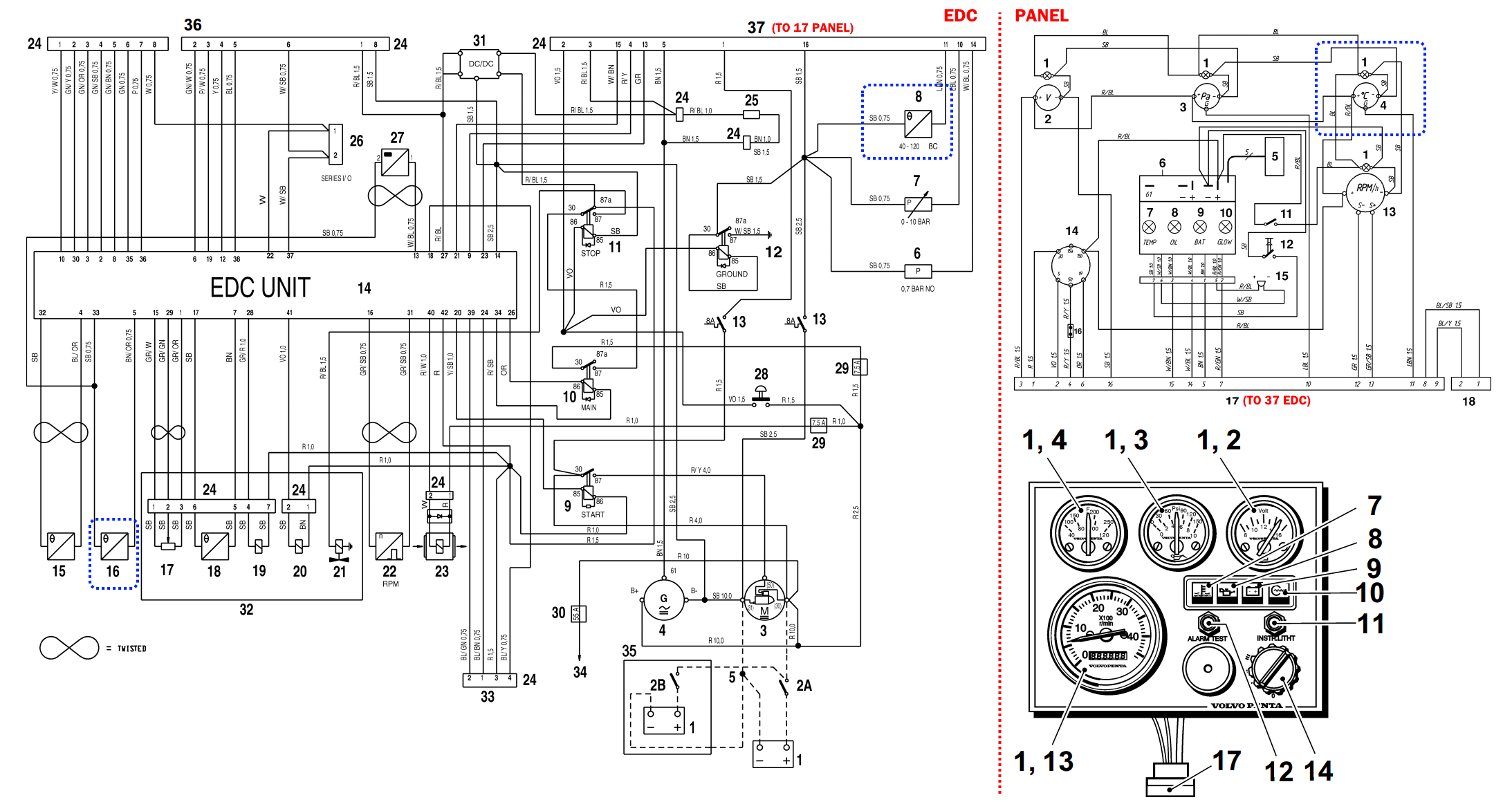

The question with temperature is more intriguing. Why do some users have the problem, and some do not? The answer is in the wiring diagram (see below). KAD have two sensors (see blue boxes, click on screenshot to enlarge it), sensor 16 is connected exclusively to the EDC and sensor 8 is connected exclusively to the coolant temperature gauge on the panel. Both sensors measure coolant temperature. One of our customers observes a stable difference of 10 °F.

Picture 1. KAD44 wiring diagram (click to enlarge)

The issue is in NTC thermistors, and they usually have non-linear characteristics. However, we hope that with the help of the settings KAD_COOLANT_ADD and KAD_COOLANT_MUL, you can adjust readings if you face this situation. The first setting is a number from -32.7 to 32.7 degrees Fahrenheit (0 by default) and the second is from 0.0001 to 6.5 (1 by default). The Gateway adds the first value to the received data and then multiplies the result to the second.

For example, 50°F is transformed to 60°F with the following settings:

KAD_COOLANT_ADD=-0.5 KAD_COOLANT_MUL=1.2122

The Settings KAD_VOLTAGE_ADD and KAD_VOLTAGE_MUL do the same for Voltage. Of course you do not need to change both parameters. It looks like the following settings work well for our customer with 10°F difference in readings (picture at the beginning of this article):

KAD_COOLANT_ADD=-10 KAD_COOLANT_MUL=1

We think that this is the best that to align readings of different instruments measured by different sensors. We are waiting for your feedback!

We also want to remind about the HOURS_OFFSET setting (present since version 1.0) which allows adding the required number of seconds to engine hours to align readings on old non-digital counters and in NMEA 2000 if your EDC unit has been replaced and reports engine hours since installation.

The firmware update is available in Downloads section.

Next articles:

- CAN Log Viewer update with DTC support for J1939 engines / December 6, 2017

- Web Gauges and new sentences support / November 16, 2017

- CAN Log Viewer update 1.06 for Windows, Linux and Mac

OS X / November 8, 2017

Previous articles:

- Happy New Year and Merry Christmas / December 25, 2017

- Meet us at the Dusseldorf Boat Show / January 17, 2018

- Yacht Devices at Boot Dusseldorf 2018 / January 30, 2018

See also: recent news, all news...