July 24, 2024 Anchor alarm function added to YDAB-01

New Alarm Button firmware adds anchor alarm mode, allows to monitor temperatures from external sources and improves AIS MOB handling.

With the invaluable help of our dear distributors and customers we have managed to add new functionality to our Alarm Button and fix some minor issues.

It is well known that most modern MFD/chartplotters and even marine smartphone apps support Anchor Alarms, but MFD/chartplotter is usually either not installed in the crew quarters or its sound is too puny to wake up the tired crew members. Smartphones are on the other hand, not so reliable, — their battery can be discharged over night or they can easily lose GNSS position signal deep inside the vessel or lose Wi-Fi connection to NMEA 2000 network (via Wi-Fi gateway or plotter).

Mr. Matthias Busse have proposed to make an Anchor Alarm out of our YDAB-01 button as a more reliable solution: first, YDAB-01 has a direct access to a wired GNSS data sources via NMEA 2000 network and second it can play really loud and noticeable sounds (you can even use your own custom sound).

In Anchor Alarm mode, device can be armed to monitor vessel GNSS position (received via PGNs 129029 and 129025, with 129029 data used with higher priority). If the position is detected to be outside of the set radius or if GNSS data are lost for a set timeout interval, a corresponding alarm event will be activated.

To arm the device, just press and release the button. If you got valid GNSS position data in NMEA 2000, device will be armed and its LED will shine constantly. If vessel position is detected to be outside of the set radius, event 1 will be triggered: linked sound will play and linked LED indication sequence will be shown.

If NMEA 2000 GNSS position data will be lost or becomes invalid for more than set interval, event 2 will be triggered: linked sound will play and linked LED indication sequence will be shown.

To disarm or cancel an active alarm event press and release the button.

You can put YDAB-01 into Anchor Alarm mode either via external button or with the command:

YD:MODE ANCHOR

You can configure the radius, time interval and GNSS timeout interval with the command:

YD:ANCHOR [1..1000 [0..600 [1..60]]]

where the first parameter sets the radius from current position in meters, default 50 meters. Second parameter sets for how many seconds the vessel position should be out of the radius before an alarm event 1 is triggered (default 3 seconds). Third parameter sets for how many seconds the GNSS position can be lost before an alarm event 2 will triggered.

Persistent arming mechanism also was implemented, you can enable YDAB-01 to save current position and into NVRAM when armed, if enabled with command:

YD:PERSISTENT ON

the device will re-enter armed state even when NMEA 2000 power is cycled ON/OFF. This increases Anchor Alarm reliability even more, as power issues may be induced by service jobs performed when on anchor.

The Alarm Button can signal when it receives an error or warning flag from the engine, or it can be programmed to the operating range of the engine indicators and monitor the indicators and signal when values go out of range. We have added an option to monitor "Engine Room" and "Exhaust Gas" temperatures via PGNs 130312 "Temperature" or PGN 130316 "Temperature, Extended Range".

If your engine does not report Exhaust Gas alarm (via PGN 127489 engine alarm data field, flag "EGR System") you can use an external NMEA 2000 temperature sensor, for example, our Exhaust Gas Sensor YDGS-01 and set up Alarm Button to trigger an engine alarm when temperature is over the set threshold for set amount of time. Our Digital Thermometer YDTC-13 sensor can be used as well for monitoring the "Engine Room" temperature.

Note that those sensors should have the same NMEA 2000 temperature instance as YDAB-01 target engine instance.

Several users were puzzled when AIS MOB alarm is activated on YDAB-01 but there is no MOB marker shown on MFD/chartplotters. The reason is that YDAB-01 is too sensitive and by default reacts to "MOB TEST" messages received from AIS, while most MFD/chartplotters will ignore them. Now you can disable YDAB-01 reaction to such messages with setting:

YD:MOB_TEST OFF

Reaction to Raymarine SeaTalk Alarm messages (PGN 65288) sent by Raymarine equipment is now supported in all modes. By default, processing of SeaTalk Alarms is disabled, except alarm ID 38 "MOB" in MOB mode. You can enable and arbitrarily map SeaTalk alarm IDs to Events using command:

YD:ALARM

Again, we are very grateful for all users who helped us to improve our Alarm Button and were brave enough to invest a lot of time and effort to debug concrete issues and painstakingly following all our instructions precisely.

Firmware update for Alarm Button (v1.11) and updated User Manual are available at Downloads section.

May 8, 2024 Update for Tank and Rudder Adapters

New modes to work in parallel with modern smart gauges, including popular KUS/WEMA devices.

The main distinguishing feature of our devices is that we can not only receive data from different types of sensors, but also work in parallel with the gauges connected to the sensors without distorting their readings.

When connecting, we have to consider how the connected gauge affects the circuit we are measuring. Some modern gauges with arrow indication are actually fully digital, and the arrow of the instrument is moved by a servo motor. Some gauges are combination instruments, with the option of selecting the measurement input via a mechanical or electronic switch. For all such gauges, consideration must be given to the state when they are switched off or disconnected from the circuit being measured, and when they are switched on.

Today's update was created back on April 11 and sent to some of our users, to test the operation with their gauges. We are publishing it with almost a month's delay as soon as we managed to gather positive feedback from all our testers, for which we thank them very much.

The update adds a new 1COIL_REF mode, for connecting smart gauges with high-impedance input. Also improved support for smart gauges with low-impedance and extra internal resistive load, which include the new KUS/WEMA digital gauges. All details on settings and wiring diagrams are published in application note YDTA-YDRA-AN-001. To make the setup easier, we have prepared for you a Microsoft Excel file that will help you to perform the necessary measurements, calculate the required parameters and prepare a configuration file or a list of commands for our devices.

The update also adds a new HYBRID mode for instruments with a DC source in the measuring circuit. When the gauge is switched off, our devices switch to RESISITIVE mode, and when there is voltage on the measured circuit, they switch to VOLTAGE mode.

Firmware updates for the Tank Adapter YDTA-01 (1.08), Tank Adapter YDTA-04 (1.05) and Rudder Adapter YDRA-01 (1.05), are available on the Downloads page.

April 19, 2024 AIS Weather Data

Update for all gateways with NMEA 2000: NMEA 2000 Wi-Fi Router and Gateway, Ethernet Gateway, USB Gateway and NMEA 0183 Gateway. Includes weather data, new Web Gauges and other cool features.

Formally speaking, AIS message #8 is capable of transmitting various types of data: data on navigational hazards, fairways and VTS, text messages and much more (see the list!). However, the maritime industry is very inert, and message #8 has not been widely used, despite the fact that the meteorological data format was proposed 20 years ago, in 2004.

Simrad NSX and GO7 multifunction displays, Garmin Echomap and Raymarine Axiom with the latest firmware failed to show our test NMEA 0183 and NMEA 2000 messages. However, NMEA 2000 PGN 129797 "AIS Binary Broadcast Message" support is not declared in their documentation. Below is the short list to test:

!AIVDM,1,1,,B,8>k1oKiKpB9GO>42lBPWmre0<N00,0*55 !AIVDM,1,1,,B,83aDChPj2d<dL<uM=hhhI?a@6HP0,0*40 !AIVDM,1,1,4,B,8>jR06@0Bk3:wOli;<`WPhh<1rqVBQf2V@Pdt0J82avIM2b<<Rv1t<ot=@1,2*56 !AIVDM,1,1,1,B,8>h8nkP0Glr=<hFI0D6??wvlFR06EuOwgwl?wnSwe7wvlOw?sAwwnSGmwvh0,0*17

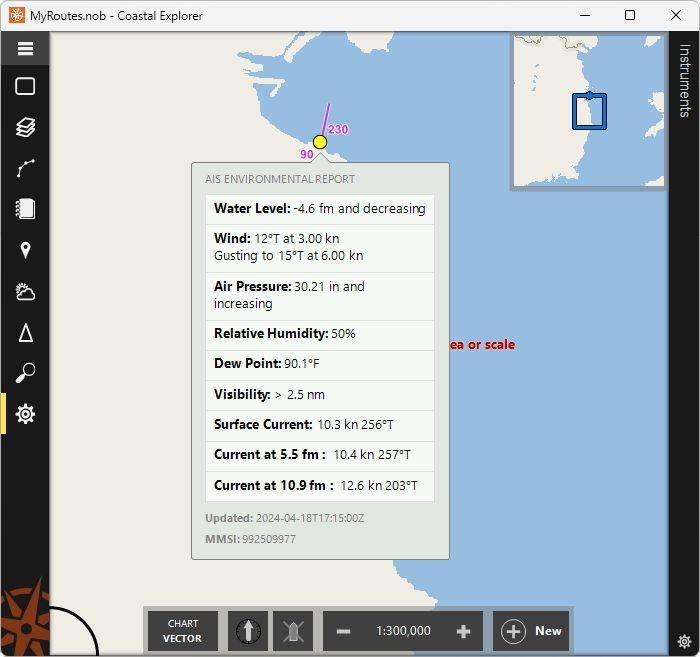

OpenCPN developers have not yet released a version with support for this message, but the work is in progress. Expedition 10 does not fully support meteorological data, and only Coastal Explorer (see image above) was able to display data from an already obsolete message (DAC=1, FI=11, proposed in 2004, obsolete in 2013), but modern messages (DAC=1, FI=31) are not yet supported.

On the one hand, it's great that support for these messages is starting to appear in software products. But on the whole it is very sad that such a simple and powerful channel of navigation and weather data transmission is not used now, and that major electronics manufacturers are in no hurry to support it. Nor have they supported Navtex, still very popular in European waters: the latest MFD to support it (Raymarine Widescreen) has been out of production for about 10 years.

In all our products that support data conversion between NMEA 0183 and NMEA 2000 (mentioned in the header), we have added AIS #8 bi-directional message conversion. Hopefully in the coming years there will be more and more places on the planet where mariners can get useful data using it, and support for it in software products will get better and better.

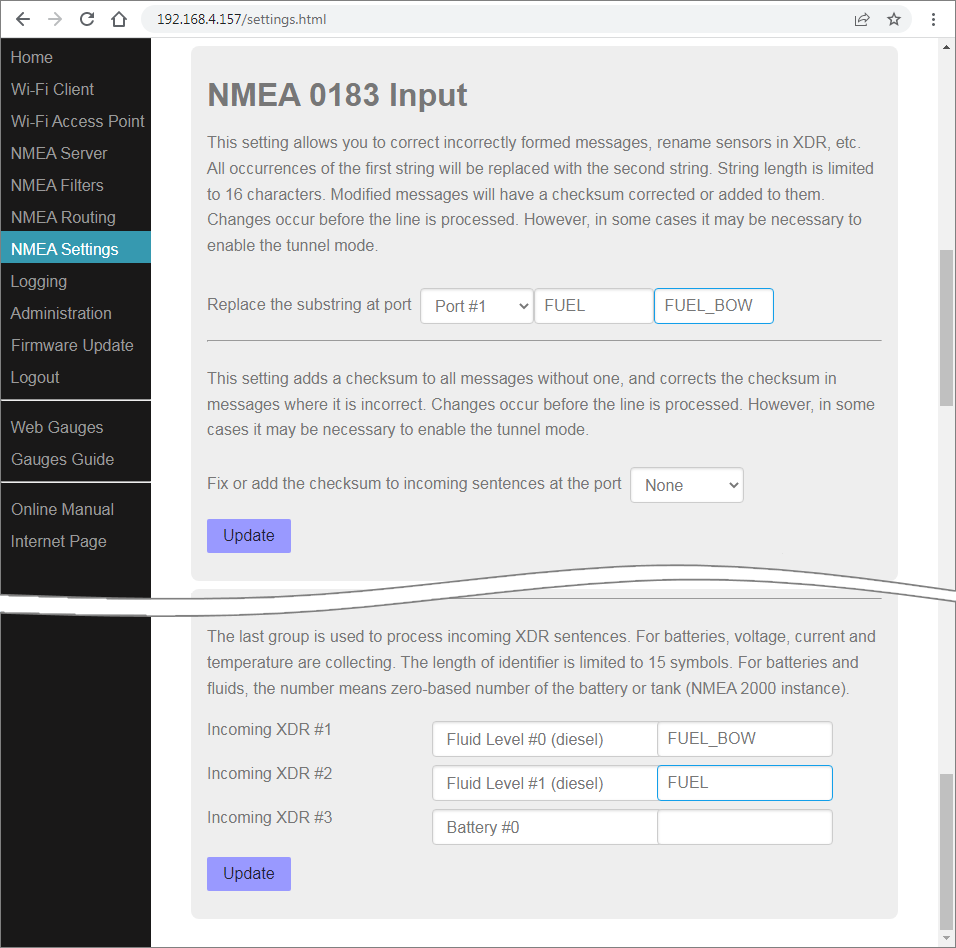

Figure 1. Substring replacement and incoming XDR

Last December we added the ability to replace substrings in NMEA 0183 messages and correct or add a checksum to our NMEA 0183 Wi-Fi multiplexers. In the firmware update for the NMEA 2000 Wi-Fi Router, we have also added these features.

They can be very useful, especially when connecting external sensors that use the XDR sentence. Suppose you have two sensors sending fuel level data in tanks in the same messages and connected to NMEA 0183 ports of NMEA 2000 Wi-Fi Router:

$IIXDR,V,15,P,FUEL*56

Since the sensors have the same sensor name (FUEL), it is the same data for our device. But we can change the name of the sensor connected to the first port from FUEL to FUEL_BOW, and then in the settings of the incoming XDR specify that this is our fore tank, and the remaining tank is aft.

Many of our devices have a tunnel function where incoming NMEA 0183 data is sent to another port without checking. If it is enabled, the units will also attempt to extract even incomplete data from incomplete messages and convert them. This is partly to support the early NMEA standards (even though they have been obsolete for over 30 years now, with the release of NMEA 0183 2.0 in 1992), partly to pass non-NMEA compliant string data between ports (e.g. Navtex receiver output).

The tunnel function was not present in the NMEA 2000 USB Gateway, as finding software that sends a message without a checksum has probably become impossible in the last ten years. However, we have added a setting that allows you to disable the requirement and checksum validation in incoming messages. To use it, give the command in service mode:

SET CHECKSUM OFF

All products with a web interface include the updated Web Gauges. It fixes a very annoying behaviour where double-clicking in some browsers would cause the screen to zoom out, it also fixes minor bugs.

New Ethernet Gateway firmware also fixes problems with uploading updates in some browsers. And added a configuration mode via NMEA 2000, useful if you have one more NMEA 2000 gateway.

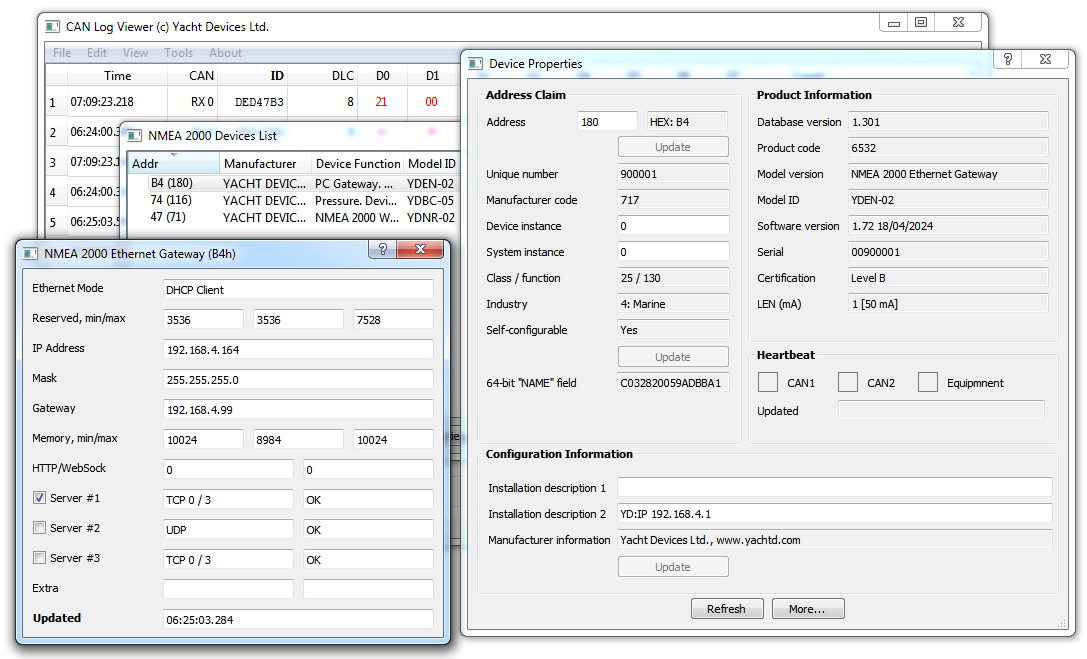

Figure 2. Ethernet Gateway settings in the CAN Log Viewer app

In the free CAN Log Viewer software you can get a list of devices on the bus and see their properties. For our products with IP interface, you can click on the "More..." button and see the current settings of the network interface.

Now, for the Ethernet Gateway, you can enter the commands in the "Installation Description 2" field (it can be done with ActiSense or Maretron software too):

YD:IP 10.1.1.3 YD:MASK 255.255.0.0 YD:GATEWAY 10.1.1.1 YD:DNS 10.1.1.1 YD:DHCP STATIC YD:REBOOT

to change the network interface settings and reboot the device. The YD:DHCP command also accepts the CLIENT, SERVER, and MAGIC arguments. All commands can be run without an argument to retrieve a stored configuration value. Note that the saved network settings in MAGIC and CLIENT mode may not match the settings in use (it is shown on Figure 2), as they may be retrieved from the DHCP server.

We recommend that all users use update 1.72 for NMEA 2000 Wi-Fi Router and Gateway, Ethernet Gateway, USB Gateway and NMEA 0183 Gateway YDNG-03. It can be downloaded from the Downloads page.

Next articles:

- B&G Fastnet Protocol / April 15, 2024

- Engine Gateway YDEG-04 Update / April 8, 2024

- New product: Python Gateway / March 27, 2024