May 24, 2019 Pressure sensor, updates for Engine Gateways

Engine Gateways can substitute engine data with data from external sensors, the Tank Adapter can be converted to a pressure sensor and work as an adapter for a Volvo Penta KAD/TAMD oil pressure sensor.

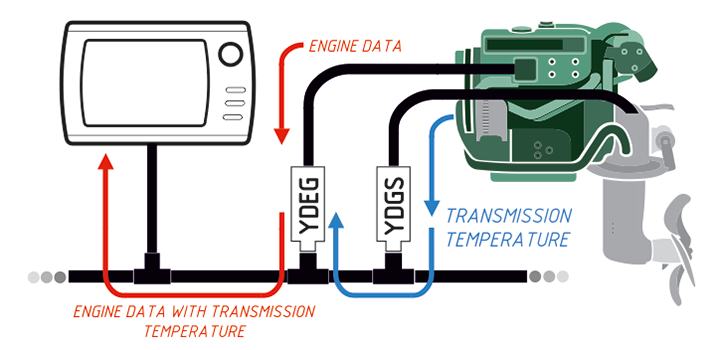

With todays update, the Engine Gateway YDEG-04 and J1708 Engine Gateway YDES-04 can use data from external NMEA 2000 temperature or pressure sensors and substitute the engines data.

For example, your engine has no temperature sensor for transmission oil. Monitoring of sail drive temperature can prevent failure, and a lathe operator can make a custom oil cap with an integrated Exhaust Gas Sensor (it can measure temperatures up to 800 Celsius). It is not expensive and an elegant solution.

Load the configuration file to the gateway YDEG-04 or YDES-04 with the following single line:

SUBSTITUTE_TR_OIL_TEMP=5

where 5 is the data instance of the Exhaust Gas Sensor (can be modified with the YD:DAT command), and it will use data from the Exhaust Gas Sensor instead of data supplied by the engine. The Engine Gateway YDEG-04 allows sensors to be connected to an NMEA 2000 network or an engine network at your choice.

In the case of twin engines (YDEG-04 only, because YDES-04 supports only one engine), for the starboard engine the sensor with data instance 6 (next value) will be used.

In the same way, you can substitute: boost, engine oil, transmission oil, fuel and coolant pressure data; engine oil, transmission oil and coolant temperature data. For details, please see Section VI.31 of the J1708 Engine Gateway YDES-04 manual or Section V.40 of the Engine Gateway YDEG-04 manual.

But what sensor to use to replace pressure data? We have many requests from Volvo Penta KAD/TAMD owners, where the oil pressure sensor is connected only to an analog gauge, and its data are not available in digital form. Of course, in this case it is better to use the existing sensor.

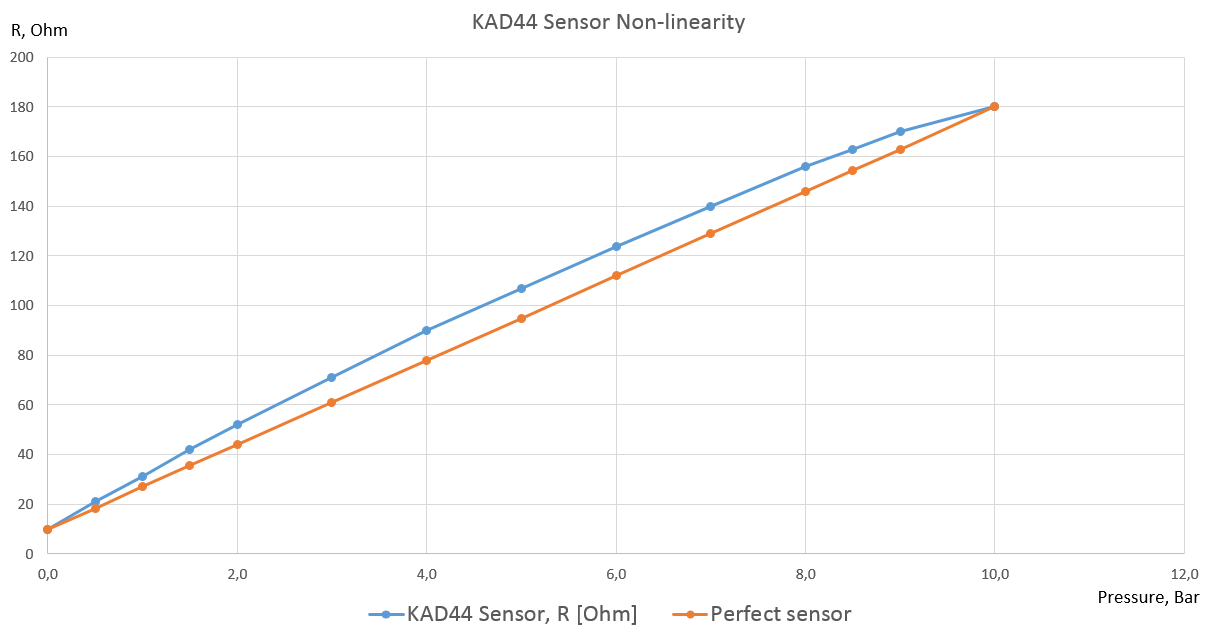

Our Tank Adapter can work with any resistive sensor up to 400 Ohm (KAD44 sensor has 184 Ohms resistance at 1000 kPa, 10 Ohms at zero pressure), it can work in parallel with digital gauges and 12V analog gauges, and it can work with 0..5V voltage sensors. Note that a Tank Adapter will not work in parallel with an analog gauge on vessels with 24V alternator and batteries, because the voltage reference input of the Tank Adapter allows a maximum 16V.

We decided do not release a new product but add a setting that converts the Tank Adapter to pressure sensor. Connect the Tank Adapter to your sensor and/or analog gauge, and configure it in the usual way. For example, it will send 0% fuel level at zero pressure and 100% at 1000 kPa pressure.

Take note that many resistive sensors have non-linear characteristics (for example, see the table of KAD44 sensor), and you may need to enter your sensors data to our calibration sheet and get a calibration string for the Tank Adapter to compensate for it.

At the final step, load the configuration file with the following line:

PRESSURE_SENSOR_PA=10000

This is the conversion rate of 1% of fluid level to Pascals (100% will 1000000 Pascal or 1000 kPa). The Tank Adapter will stop sending PGN 127505 "Fluid Level" and will send data in PGN 130314 "Actual Pressure" (please, see more details in Section VI.17 of the manual).

The update for Engine Gateway YDEG-04 also has a new tilt/trim calibration system, previously available for SmartCraft only. Now it is possible to calibrate the tilt/trim for SmartCraft, MEFI4B and Volvo Penta EVC systems.

The trim calibration is stored in the TRIM_ZERO (calibration value for zero tilt/trim angle) and TRIM_STEP (calibration value corresponding to 1% change of the tilt/trim angle) settings. The Gateway processes one of three CAN messages with tilt/trim data, depending on what system is turned on (SmartCraft, MEFI4B or EVC). Owners of MEFI4B engines should turn on the new setting MEFI4B after update (see the section V.36 of the manual) to get tilt/trim data.

Calibration for all systems now is the same, very easy and takes only a minute. To begin, set the port engine to the lowest position (0% tilt/trim), and load the configuration file with the single line:

CALIBRATE_TRIM=0

If the Gateway actually has tilt/trim data, the value of the TRIM_ZERO setting will be updated and you will see 3 confirmation green flashes. Then lift the engine to the highest position (it will be 100% tilt/trim) and load the file with the line:

CALIBRATE_TRIM=100

The Gateway will calculate the trim step corresponding to 1% and update the TRIM_STEP value. Review settings in the YDEGSAVE.TXT and modify values if required. Please, see Section V.38-V.39 of the manual for more details.

Updates for Engine Gateway YDEG-04 (v1.31), J1708 Engine Gateway YDES-04 (v1.04) and Tank Adapter YDTA-01 (v1.04) are available in the Downloads section.

Next articles:

- All the best in one product / April 17, 2019

- Meet the NMEA 0183 Multiplexer / April 16, 2019

- Tons of small updates / April 12, 2019

Previous articles:

- Trigonometry and encryption in the Bridge / July 1, 2019

- July bug fixes, AIS in Navionics / July 8, 2019

- New device: Alarm Button YDAB-01 / July 12, 2019

See also: recent news, all news...